Robotics & Peripherals

Combining patented sensing and gripping technology with a low profile plug and play design, our wafer handling tools provide unparalleled flexibility in dealing with thick, thin, or fragile wafers in all environments. All our products adhere to the most rigorous wafer manufacturing standards and requirements.

Robotics Automation Solutions

Components for Success

Innovative Robotics

Who knows SCARA robot better than we do? For a quick customization, Quartet Mechanics uses its sister company's, Innovative Robotics, home-grown IR-820 SCARA robot

- High through-put with the trajectory optimal planning design, trackless-3-FOUP reach

- CE-certified, ISO-12644 Class 1 certified, SEMI compliant

- Highly configurable - supports Vacuum, Bernoulli, Vortex, Electric-activated end effector

- Lowest Cost of Ownership (COO) with its robust mechanical desgin

- Vaporous Hydrogen Peroxide (VHP)-compatible robots available

- On-the-fly centering mechanism to eliminate aligner if wafer orientation not required

- Optional 5th-axis, ±275° flipper and vertical external or horizontal track

(see more Feature and Specification of IR-820)

Staubli Robot

We work with Staubli if a 6-axis robot is required to fulfill your cleanroom automation. Staubli’s 6-axis cleanroom robots were designed from the initial concept to comply with the stringent requirements of the cleanroom environment. Addtional advantages of superior through-put capabilities and industrial design reliability are provided. Its repeatability meets ISO 9283 , ±0,02 mm; its arm mounting options includes floor/wall/ceiling.

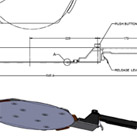

Contamination-free edge gripper & vortex gripper

Our soft-touch mechanism with programmable gripping force enables the gripping tips to gently touch the wafer on the exclusion zone only thus minimizing particle generation while maintaining a secure hold.

- The gripper’s fail safe wafer interlock mechanism prevents costly losses by holding wafers securely at accelerations exceeding 5G and during power failures

- Class 1 cleanliness certified

- Ultra-slim gripper and special gripping tip design to meet the very small pitch/clearance of the cassette (Standard 6" cassette with pitch 4.76mm used for 1.2mm thick wafer)

- Top- or bottom-pick, handles from 50 microns to 6mm thick substrates, round or square (vortex type available for ultra thin, warped and potato-chip like wafers)

- Options include self-centering, waterproof, high temperature, and integrated mapping sensor

A Pre-aligner & ID reader for Si & Compound wafers

This single axis pre-aligner is one of the fastest aligners in the market. It takes less than 2.5 seconds to align 100-200mm, 200-300mm wafers, with the repeatability of centering ±50 microns, rotation: ±0.05 degree (higher precision available upon request). It aligns standard, semi-transparent and transparent wafers with notch or flats (primary and secondary flat). It works on wafers made of silicon, sapphire, quartz, glass, epitaxy, germanium etc.

- Seamlessly integrated with IR-820 robot for on-the-fly centering and IOSS WID110 to optimize the read-fail proof and high through-put. The wafer ID reader can easily decode OCR, barcode or 2D codes regardless of the marking method (hard-marked, soft-marked or super soft-marked).

- Optional thin/warped wafer compliant aligner; contamination-free, stress-free edge-grip type

aligner

LED light Detection

Our home-grown precision thru-beam sensors are specially designed for wafer mapping, aligning and positioning. They are designed to prevent production line stoppages and expensive crashes by identifying ALL wafer misplacements - stacked, cross-slotted and empty slots, especiallly compatible for wafer such as sapphire and other compound wafers.

The LTB-M model can reliably detect any wafer (including cross-slot) in a cassette, by moving a very tiny (6x6x3 mm) sensor installed on the robot arm and a string of LED source lights installed from the back side of the cassette. The sensing range is up to 1.5 meters (5 feet) and the unit will detect wafer thicknesses from 100 to 1000 microns.

Precision Matters.

Especially in the telecommunications industry where optical MEMS devices are used in switching arrays, the device must be placed with a high degree of accuracy on the order of 5 µm in the X, Y and Z directions, and 0.2 milliradians in theta. Quartet Mechanics' experience in integrated machine vision with automatic handling systems ensures the wafer placement with a high degree of accuracy needed by the MEMS industry. For example, fiducial marks are used by the machine's automated vision system to recognize and correct the device's location. Our in-house precision manufacturing and measurement facility assures the fabrication of each component's precision to spec.