As the semiconductor world pursues new process technology for next generation product, it brings profound difficulty and complexity of wafer handling on the manufacturing floor. Wafer-handling.com is a company in Silicon Valley established to meet today and tomorrow's wafer handling needs. Wafer-handling.com is equipped with 20-year experience in developing intelligent wafer handlers for robotic automation to serve global automation companies and semiconductor OEM equipment makers and fabs.

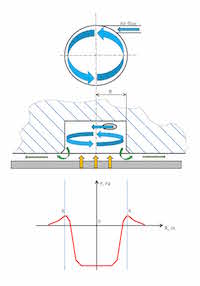

Our expertise lies in handling fragile and specialized wafers; all components are manufactured in-house to easily adapt to clients' needs. We developed a comprehensive line of non-contact (exclusion zone contact only) thin wafer handling solutions suitable for 4"~12" notched or flatted, opaque/translucent/transparent, thin, warped, or Taiko wafers.

We offer standard plug-and-play and custom products that are compatible to most robots in the market. With the sophisticate sensors designed in each product, it prevents wafer breakage and edge-chipping. .

| EVENT | BOOTH# | CO-EXiHIBIT |

|---|---|---|

| Semicon Taiwan, 2024 | R7522 | Wonder Automation Inc. |